Simulation Technology plays an important role in the process of automobile production. According to the manufacturing stage of automobile products, it can be divided into CAD, CAE and CAM, with sources & ldquo; automotive Simulation Technology& rdquo;.

Among them, CAD is used for early-stage product design, CAE is used for product performance and structure analysis; CAM is used for the landing of product production and manufacturing; CAD uses digital model for industrial design, assist engineering and technical personnel to complete product design, thus improving product development efficiency, reducing development cost and shortening development cycle. According to statistics, after the application of CAE technology, the proportion of development period expenses to development costs decreased from 80% to 8%.

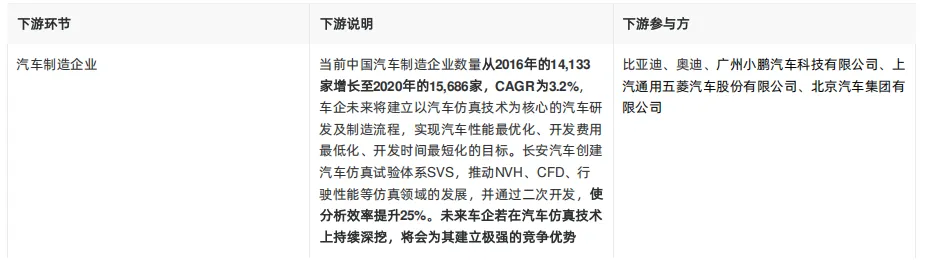

Toubao predicts that in the future, the penetration rate of China's Automobile simulation market in the downstream will maintain a steady growth, and the market scale of automobile simulation will be 3.3 billion yuan in 2021, with a compound growth rate of 15.4%, it will reach 7.78 billion yuan in 2026.

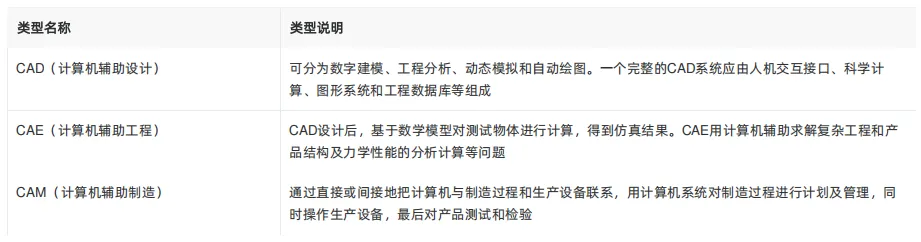

1. Industry definition of automobile simulation technology

simulation Technology is a multi-disciplinary comprehensive production that uses computers and establishes models to carry out scientific experiments. It has the characteristics of economy, reliability, practicality, safety and reuse. Simulation technology can be divided into CAD, CAE and CAM according to product manufacturing stage, among which CAD is used for early product design, CAE is used for product performance and structure analysis, the landing CAD of CAM used in product production and manufacturing uses digital model to assist engineering and technical personnel to complete product design, thus improving product development efficiency, reducing development cost and shortening development cycle. CAE is a further simulation analysis of the real world on the basis of CAD to realize scientific and information management of the whole process, which not only reduces manufacturing losses, but also saves costs, achieve excellent engineering quality with good economic benefits. CAM is a product production based on CAD and CAE data to make products fall into the ground quickly. CAE is the core of the three technologies and the key development technology in the simulation field. It is applied to many industries, especially automobiles, aerospace and other industries with complex manufacturing and high test costs. In the future, with the maturity of CAE, the application scope of simulation technology will continue to expand.

2. Industry classification of automobile simulation technology

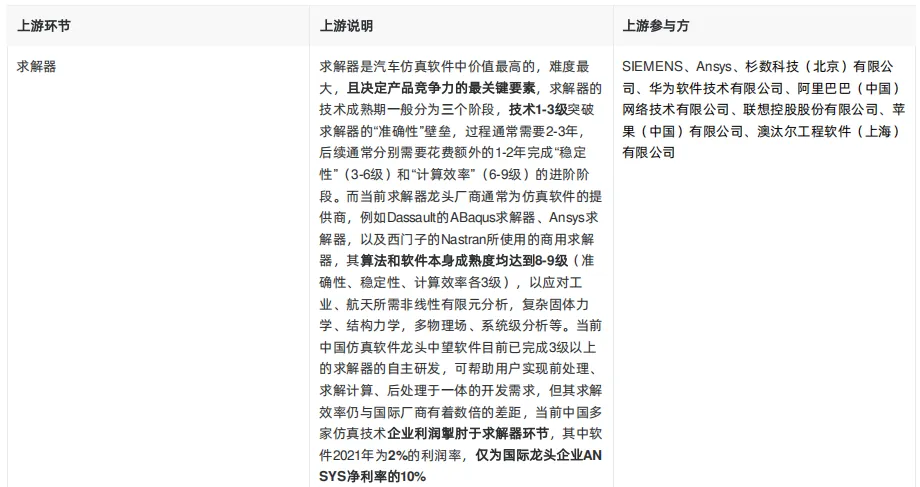

the Automobile simulation technology industry is divided into three industries: CAE/CAD/CAM, of which CAE is the core of the three technologies and the key development technology in the simulation field. It is applied to many industries, especially automobiles, aerospace and other industries with complex manufacturing and high test costs. Since technology 2.0, simulation technology has played an important role in the field of automobile research and development. Solver is the core of CAE, with the highest value and great development difficulty.

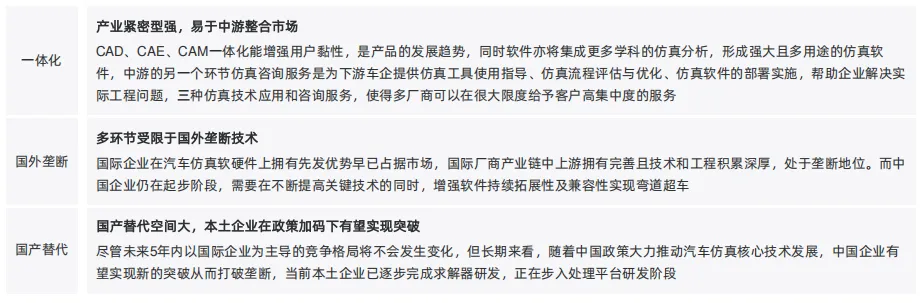

3. Industry characteristics of automobile simulation technology

the Automobile simulation technology industry is a process of using computers to establish models for scientific experiments, which is applied in many scenarios such as automobile design aerodynamics analysis, vehicle collision simulation, stiffness and strength analysis, etc. Due to the first-mover advantage of foreign technology, the industry is still in the market environment of foreign monopoly, but the scale of domestic substitution is large in the future, and local enterprises are expected to take off.

4. Development history of automobile simulation technology

automobile R & D technology is divided into four stages according to Human Participation & mdash;& mdash; Design of physical test drive driven by pure human intervention, design of computer aided simulation drive, computer-led big data-driven design, AI and Super Brain decision-making artificial intelligence-driven design. From technology 1.0 to technology 3.0, per capita is the most critical and core element, but in the case of technology 4.0, the role of engineer is subverted, from the main R & D executor to the super brain monitor, to ensure that the super brain performs tasks accurately. Since technology 2.0, simulation technology has played an important role in the field of automobile research and development. Even though human participation will gradually decrease in the future, simulation technology is still widely used. Big data drive and artificial intelligence Drive are only the steps of manual operation and decision-making, while the underlying architecture still needs simulation technology to provide data support for super brain, so the role of simulation technology in automobile manufacturing cannot be shaken.

5. Industrial Chain Analysis of automobile simulation technology

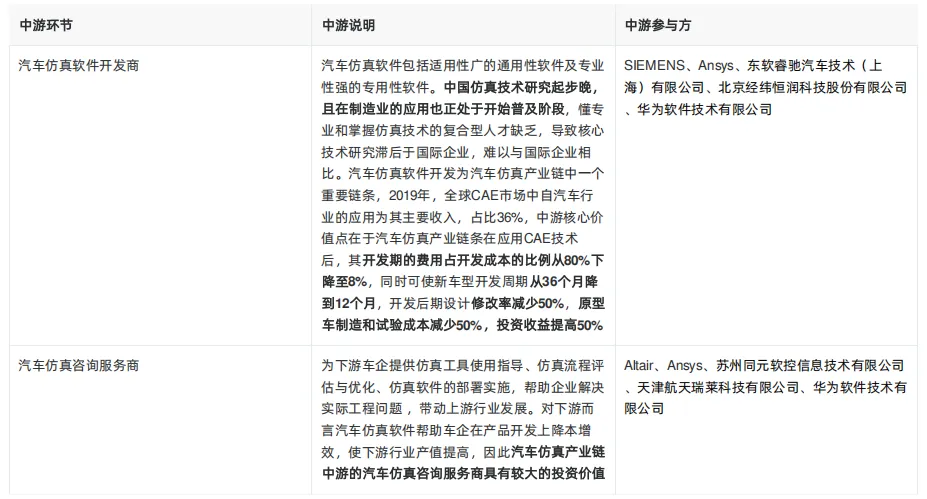

the main players in the upstream of China's Automobile simulation industry chain are the basic software and hardware equipment suppliers of core software mainly composed of Siemens, Microsoft and Apple;

in the middle reaches, the Automobile simulation software developers and consulting service providers mainly focus on ANSYS and Siemens Autodesk extend the layout to the automobile field with the core simulation technologies CAE, CAD and CAM integrated in the industry as the center.

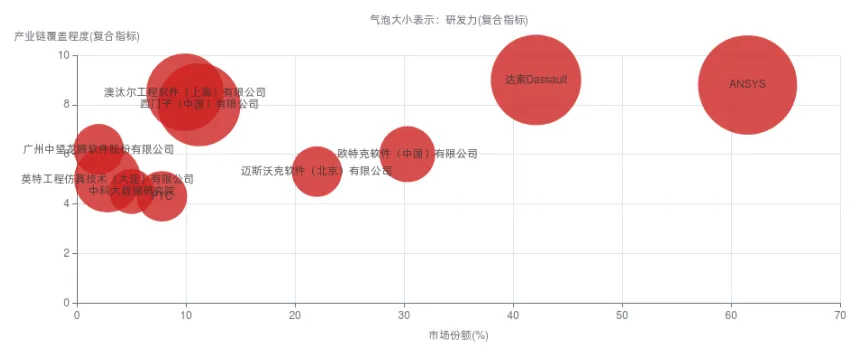

The downstream is an automobile manufacturing enterprise, which needs to use Automobile simulation technology to increase its competitiveness. Taking Chang'an Automobile as an example, it saves sample cars by using Automobile simulation technology, make the dynamic performance and thermal management system have the same effect as the mass production version, and at the same time greatly reduce the wind resistance of the vehicle the upstream of the Automobile simulation technology is mainly the core software solver, basic software and hardware equipment, among them, the solver has the highest value as the upstream core software based on its characteristics of long development cycle (3-5 years) and high development difficulty (intellectual property barrier), it is also the most difficult link to achieve short-term breakthrough.

International enterprises such as ANASYS(31.4%), Mathworks(22.2%), Siemens (10.6%) and so on are the dominant players in the middle reaches, however, the market share of Chinese manufacturers mainly based on Intel project and Zhongwang Longteng is less than 10%, while the influence of basic software and hardware equipment on the midstream is further squeezed as the profit margin of Chinese manufacturers, for example, Dassault and ANSYS, the current industry leaders, have net profit margins of 15.6% and 21.3% respectively in 2021, while as the only one in China that has mastered CAD, CAM, zhongwang International, the manufacturer of CAE core technology and product development capability, had a profit margin of only 2% in 2021;

the middle reaches are the developers and consulting services of automobile simulation software. The main industrial software such as CAE and CAD cover many basic disciplines, which requires long-term technical accumulation of participants. While the downstream of the industry is connected with automobile manufacturers, although a complete simulation system requires high installation and service costs (taking Ansys, the leading manufacturer in the simulation industry, as an example, NASA spent 39.1 million US dollars, about 0.25 billion RMB bought the 5-year use right of Ansys) to complete the space design phase and save a lot of verification links.

While downstream car companies are more willing to save a lot of research and development costs and research and development time make car companies more willing to buy car simulation software, which brings huge economic benefits to car companies, it can effectively optimize product performance and save a lot of time and cost from design to testing. Analysts believe that automobile enterprises will widely use Automobile simulation technology in the future, the middle reaches will exert great potential to promote the development of upstream industries, and at the same time help downstream reduce costs and increase efficiency, which is of great value. The scale of China's Automobile simulation market will increase from 3.3 billion yuan in 2021 to 7.78 billion yuan in 2026.

6. Scale of automobile simulation technology industry

by 2026, the market scale of automobile simulation will reach the market scale of 7.78 billion in 2026 from 15.4% CAGR in 2021, among which CAE will grow fastest after 2021, CAGR is close to 20%, the growth rate of CAM and CAD is 12.7%

at present, under the background of the transformation of enterprises to intelligent manufacturing and the increasing recognition and attention of downstream customers to simulation technology, the importance of simulation software to assist the research and development of enterprise products has gradually become prominent, its penetration rate is gradually increasing, and the market scale of the overall simulation industry will show a rapid growth trend. Among them, the application proportion of simulation software in automobile manufacturing is 31%, which is the highest proportion in downstream. The Automobile simulation market will also show a trend of rapid growth. The income sources of Chinese automobile simulation software manufacturers are simulation software sales and simulation business consulting services. Among them, the unit price of a set of basic Enterprise Automobile simulation software is 1 million yuan. At the same time, Automobile simulation software is more willing to save a lot of research and development costs and research and development time for automobile enterprises to make automobile enterprises more willing to buy Automobile simulation software, which brings huge economic benefits to automobile enterprises, can effectively optimize product performance.

Analysts predict: in the future, the technology end of automobile simulation software will continue to expand under the demand of new energy vehicles and aerospace, driving more application of simulation technology in the field of automobiles, so as to accelerate domestic manufacturers to replace CAE, CAD and other technical fields, and the domestic automotive simulation field is expected to release great potential. On the other hand, the policy encourages to promote the transformation of manufacturing industry to digitalization, and improving production efficiency will also increase the application of automobile simulation software by automobile enterprises to promote product research and development and production, thus driving the sales volume of simulation software and the growth of consulting business.

7. Competition pattern of automobile simulation technology

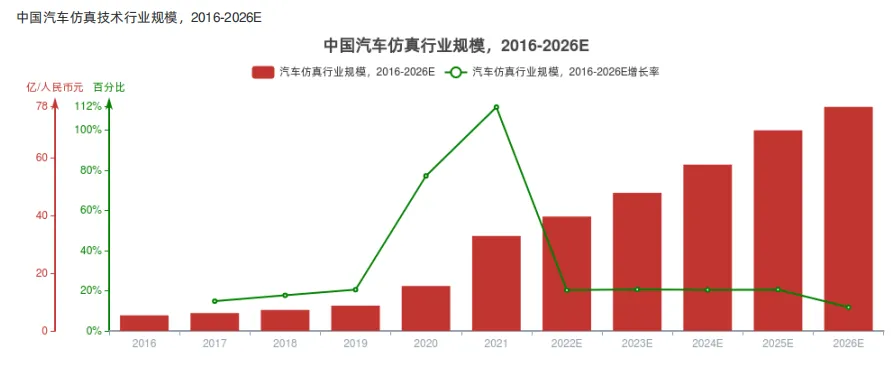

international enterprises are in a monopoly position in Automobile simulation software, and there is a big gap between Chinese enterprises and international enterprises. Judging from the global 3D/2D CAD and CAE comprehensive market share in 2020, Siemens (CAE accounts for 10.6% of the market share, CAD accounts for 0.6%), international enterprises such as Dassault (CAE accounts for 31%,CAD accounts for 11.1% of the market share) and ANSYS(61.5% of the market share is ahead of CAE market), in terms of the higher CAE market share of value, international manufacturers account for almost all market shares, among which CR5 accounts for up to 88.9%, including Ansys, Mathworks, Altair in the United States, Dassault in France and Siemens in Germany. In addition, international automotive simulation software giants not only provide CAE software, but also provide sales and CAE consulting solutions for core technologies such as solvers and general modules. However, CAE consulting business requires extremely high requirements, it requires engineering experience accumulation and physical analysis ability to provide customized services for customers.

Compared with the advantages of international manufacturers in Automobile simulation software, such as wide coverage, leading core technologies and complete functions, the key technologies of Chinese CAE software developers have a low degree of self-control, and in productization, there is a big gap between integration and scale and international manufacturers, and the whole is still in the development stage. Therefore, the competition pattern led by international enterprises will not change within 5 years. However, in the long run, based on the need of vehicle enterprises to face the rapid iteration of intelligent networking technology, automobile simulation software correspondingly adds many dimensions, such as continuous expansion and compatibility, which is still blank for market participants and provides opportunities for Chinese automobile simulation software manufacturers to overtake in corners. With China's policy vigorously promoting the development of core technology of automobile simulation, Chinese enterprises are expected to achieve new breakthroughs and thus break the monopoly.

This article is reprinted from: architect Technology Alliance

Reprint

Reprint